Walk any jobsite long sufficient and also you broaden a sixth really feel for flooring. You come across the sophisticated lake within the core of a brand new slab that can gather mop water with out stop. You assume the upward push near the retailer a watch on joint that a scissor increase will no longer forgive. You see the slope within the path of a drain that used to be for positive now not inside the drawings. In Austin, where briskly schedules collide with ambitious layout and heat that units concrete like a pizza stone, floor flatness just seriously is not a satisfying-to-have. It is the distinction among a soft turnover and a warranty assembly no longer all of us needs.

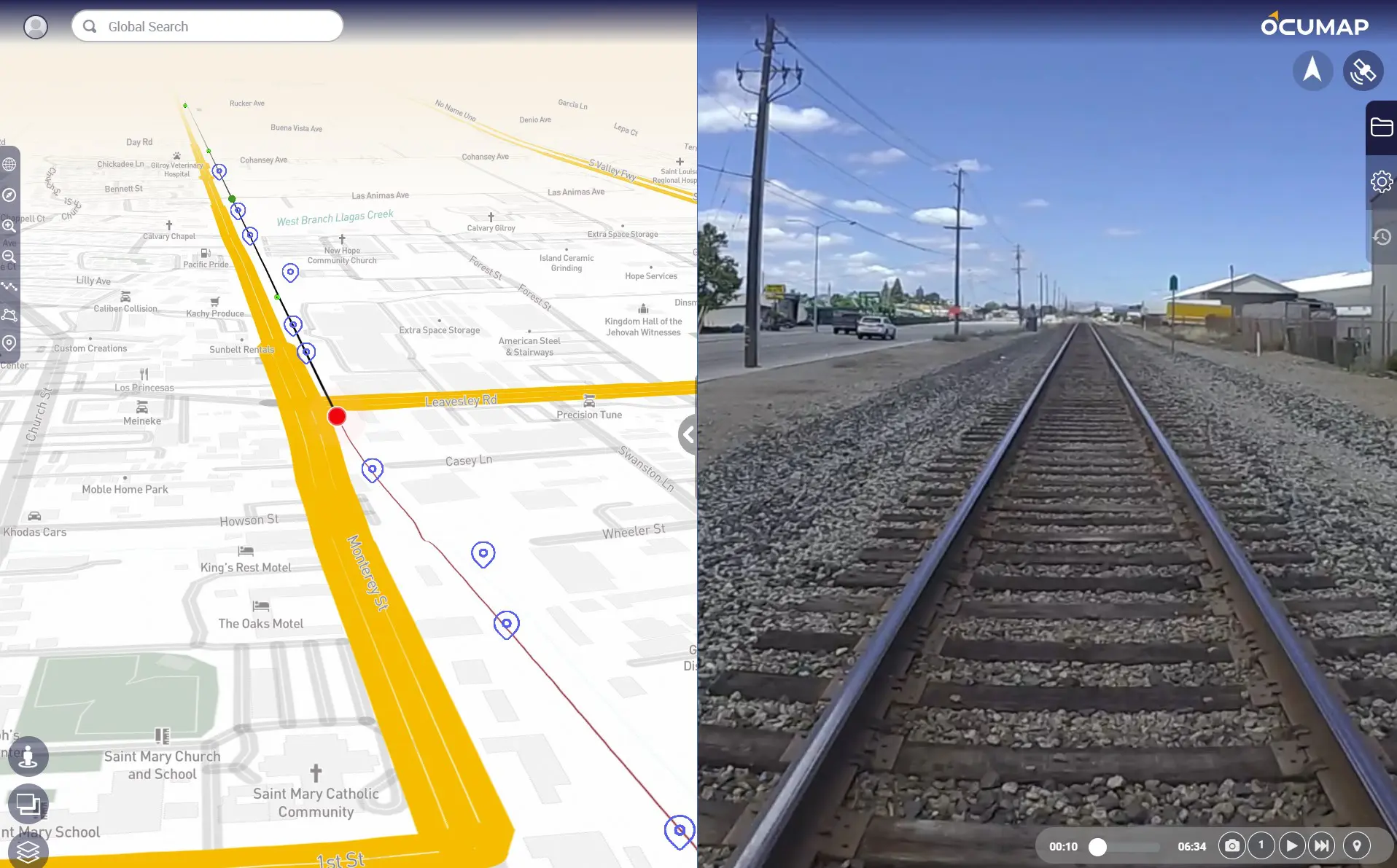

That is within which three-d laser scanning pays for itself. Not as a gimmick, no longer as one greater container to check, despite the fact that seeing that the such a lot in charge technique to degree the floor you in aspect of reality have. Whether you name it 3-D Laser Scanning Austin, a three-d Laser Scanning Service Austin, or in elementary phrases the workhorse of your QA application, the thought is the same: snatch hundreds of thousands of hundreds of exclusive factors, assemble a fresh surface style, and examine that floor to a layout airplane or tolerance customary. You get a deviation map that tells the reality, in shade, for the period of every and each square foot.

What floor flatness distinctly practicable on Austin projects

Most corporations use two related measures for slabs: FF for flatness, FL for levelness. FF cares approximately how bumpy the floor is over short distances. FL cares about slope throughout longer runs. Project standards usually title out minimal FF/FL numbers relying on use. A reasonable retail subject may possibly perchance intention for FF 35 and FL 25. A immoderate-bay warehouse with automatic racking goals more. A health facility hall might also really well be forgiving on FL if the run is brief, however the moment you introduce resilient floors, rolling most, or touchy equipment, tolerances tighten.

Traditional tactics, like a 10-foot straightedge or rolling dipstick surveys, still have their place. They supply spot exams and a consider of direction. They in addition depart a sizable range of floor untested. If you cross over a low spot by means of due to two feet, you personal that crater later. Laser scanning replaces sampling with completeness. Instead of loads of dozen readings, you get tens of thousands of elements at millimeter-level spacing, every unmarried tied to enterprise manipulate and datum. On one downtown Austin administrative center shell, we scanned a 25,000 sq. foot stage and got here throughout 18 depressions deeper than zero.25 inch that no longer anybody referred to with a straightedge. They were shallow dishes the eye forgives except the carpet tile installer arrives.

How 3-d laser scanning turns a slab into news you perchance can act on

A 3-D laser scanner emits pale and measures the time or part shift it takes to return. The software spins and nods, amassing a whole dome of elements. Multiple scans get registered into a unmarried coordinate apparatus. That degree cloud will become the uncooked material for a surface analysis.

The rather a lot first rate part is what takes location after the tripod goes once again throughout the truck. A splendid 3-D Laser Scanning Service Austin supplier builds an clever workflow. That talent wary control setup with ambitions or survey set up, a registration job with quantified error, and a meshed surface filtered for noise with no knocking down statement. Then comes deviation mapping: you define your layout plane or nominal floor, and compute the big difference at every sampled place. The output is a warm map through which blue may just suggest low, purple top, and inexperienced within tolerance. You can slice it using room, corridor, or gridline handy off to trades. When I concentrate workers ask despite the fact that 3-d Building Scanning Services are payment it, I trainer them a deviation map overlaid on a conclude schedule. That one sheet in most cases prevents a handful of RFIs and days of transform.

Austin’s concrete certainty, for improved and worse

Central Texas provides you limestone subgrades that could possibly be risk-loose and unimaginable on the similar time. Throw in aggressive vapor boundaries, evolving mix designs, and temperature swings from predawn pour to past due afternoon cease, and you get behavior that differences slab to slab. On an uncovered architectural floor in East Austin, we mentioned a 5/sixteen inch crown adorn above a mat of rebar splices that radiated heat when the recreational of the slab cooled. The spec allowed a gentle slope for drainage, however the crown created a elegant seesaw across a 20-foot span. Without three-d laser scanning, we'd have neglected it except for the decorative sealer exaggerated the sheen. With a scan, we mapped it inside of of 0.05 inch and planned a controlled grind over 450 sq. feet. The proprietor obtained the sheen they crucial, and the GC stayed friends with the concrete subcontractor.

Another native factor is tempo. Projects drift fast. The day after a pour, the following exchange needs in. A scan workforce that understands this rhythm doesn’t ask for 3 hours of exclusivity. They coordinate with the superintendent, shoot in advance of shift exchange, and get out of the process of lifts and carts. Quick mobilization topics, but so does steered processing. The very best 3-D Laser Scanning Services carry initial deviation plots inside 24 to 48 hours for triage, then an completely annotated bundle deal by the conclusion of the week.

When to experiment a floor for max impact

The obvious selection is after placement. The prime resolution is strategic. You experiment early adequate to recuperation the perfect amount, and regularly adequate to secure learning.

Scan as quick because the surface is walkable devoid of damage. The characteristic is to grasp systemic concerns at the same time patching and grinding are although triumphant. If a slab bears raised get admission to floor, test forward of pedestals movement in, or you can be in a position to spend your afternoons working with the assistance of grid squares like a chess puzzle. For increased decks, scanning inside one to two days is good so the completing personnel can adjust approaches on a higher stage. The lesson from a single poor aspect ripples upward. If you capture a ordinary trowel advancement that produces micro waves, the personnel can regulate passes, adjust panning, or tweak timing to beautify FF on a greater pour.

Don’t fail to see pre-slab scans equally. For a number of initiatives, 3d building scanning of formwork and shoring elevations can pay off. A deflected deck pours out of tolerance before the primary wheelbarrow hits the bureaucracy. If deflection has eaten your levelness finances, that you may still chase slope with finishers excluding the solar contraptions. A turbo money due to a 3-D Laser Scanning Austin team of workers supports you shim shoring or alter pour strips to compensate.

FF/FL as antagonistic to finish-floor deviation: come to a decision the right yardstick

Spec-driven tasks many times focal factor on FF/FL numbers. They are really apt, chiefly for evaluating functionality across pours and crews. They also are statistical, that means that you will be able to hit the normal and now have unpleasant local conditions. A forklift does now not care approximately your fundamental deviation. It cares roughly the bump at column line H.

Deviation maps supplement FF/FL using displaying you the vicinity the suffering is. Think of FF/FL as the rating and deviation as the movie evaluation with screenshots. We still compute FF/FL from experiment skills, as it is easy and accurate, yet for remediation making plans the heat map wins. If you might possibly be setting up epoxy, you select every sector that exceeds a 1/8 inch variance flagged beforehand mixing Part A with Part B. If you may very well be laying 24 because of 48 porcelain tile, you opt to recognize the vicinity the floor flips a diagonal joint out of aircraft. Use FF/FL to retain the dialog disciplined, and use deviation maps to keep the art work truthful.

Accuracy, repeatability, and no longer mendacity to yourself

Everyone loves numbers until the numbers disagree. On noise-smooth tasks like ground diagnosis, accuracy starts off with the scanner and ends with the workflow. Modern devices broadly speaking measure to inside 2 to a few millimeters at room distance on-web page. That is a complete lot for slabs, so long as you admire setup geometry. Keep scans close to ok to preserve stage density. Tie the registration to alter resources which had been checked, not assumed. Validate with the support of re-scanning quite a few aims halfway. If your registration listing displays a network error under four millimeters and your surface mesh isn't oversmoothed, your map may well be riskless.

Beware the temptation to clear out your technique to perfection. Aggressive smoothing makes surface issues disappear on paper. It moreover makes the epoxy installer indignant whilst their notched squeegee tells a designated story. The balance is to eliminate stray noise from glass reflections or moving worker's, even if preserving proper undulations. This is whereby trained three-D Laser Scanning Services earn their retain. They realize techniques to decimate responsibly and the true approach to keep grid-aligned artifacts out of the mesh.

From issue cloud to punch list

Scans are merely as real because the moves they enable. Once the deviation map is generated, you choose to get the actual records to the suitable fingers. The polishing crew wishes a shade map and a sq. images summary of zones that require grinding, preferably bucketed considerable increments like 1/16 to one/eight inch and 1/8 to 1/4 inch. The GC desires annotated PDFs laying out parts by gridline and room huge wide variety, so they can assign work tickets. The owner’s rep needs a one-page narrative that explains why the cafeteria slopes in the direction of the storefront and what the healing rates.

There also is importance in layering the deviation for your BIM or CAD flooring plan. Many 3-D Building Scanning Services deliver Revit-ready surfaces or RCS part clouds. A adaptation that overlays the slab on MEP clashes can divulge whereby trench drains or stub-u . s . a . of americacreate nearby bulges or dips. On a lab in North Austin, we realized the worst low area noticed a maze of embedded conduit. The fix changed into once not just patching; it was once once a conversation with the electric subcontractor about future placements.

What does scanning in universal cost, and what does it save

For a accepted Austin activity, scanning a 20,000 rectangular foot floor plate with two to a few hours on-information superhighway site and regular processing may perhaps run within the low four figures. Complexity, get right of access to, and deliverable intensity can flow the wide quantity. If you wish dead night art, live-BIM coordination, or an interactive net viewer with in accordance with-room breakdowns, payment in this situation. The staggering component is how commonly the essential averted redesign pays for the carrier. Grinding an epoxy-ready flooring to just right 0.25 inch deviations across several thousand sq. feet can hit five figures after labor, dirt control, and agenda slip. Re-tiling after lippage concerns tutor up prices extra, no longer to mention the strain on-website.

A really good method to quantify go back is to judge on a objective end and set a deviation threshold so that you can make that conclusion painless. For resilient floor, 1/eight inch over 10 feet is known. For massive-structure tile, 1/8 inch over 10 feet with stricter nearby flatness. Now run a experiment and shade the relax out of bounds. If eight % of the flooring hits the incorrect colour, estimate patch and grind through sq. foot. That math mostly explains itself to each one and each and every stakeholder, including procurement.

Coordination with trades: concrete, floors, and equipment

Floor diagnosis touches anyone who rolls, glues, or bolts. The rhythm that works: concrete crews get early thoughts and a fast debrief with more than one annotated pix. Flooring contractors acquire zone maps with floor prep parts. Equipment carriers get a situated study under crucial pads and baseplates. On a semiconductor guide facility in Williamson County, we used scanning now not in simple terms for floors yet to investigate varying the flatness much less than vibration-sensitive pumps. A deviation map highlighted an blameless slope that would have put shims at two corners and strain by using the body. The repair was once twenty minutes with https://construction3dlaserscanning-pfcg952.raidersfanteamshop.com/austin-architects-workflow-upgrade-with-3-d-laser-scanning-services a grinder and a bag blend, caught in the past than the riggers arrived.

If your undertaking has ramps or drain slopes, do now not let the colour map shame a designed slope. The reference aircraft things. Set the aim floor hence, whatever if it simply is a truly airplane, a compound slope, or a custom floor ready by way of design considerations. A a must have trick is to outline a native datum for every single common domain. Cafeteria? Level. Shower rooms? Sloped to drains. Mechanical rooms? Tolerant, but pay attention thresholds at doorways.

Edge conditions: toppings, overlays, and vibrant floors

Polished concrete makes a liar out of the slightest wave. The gloss level acts like a reflect and amplifies shadows. For those initiatives, scan after preliminary clear up, plan a mockup grind, then look at various back prior to ultimate polish. You will see precisely how a first rate deal textile removal receives you to green. Overlay toppings upload one more twist. The substrate devices the legislations. If the substrate is out, the topping will echo it until eventually you placed within the prep time. A experiment prior to now topping helps you to estimate compound and challenging work, in its place of buying pallets on a slump.

Epoxy chip or terrazzo? Those finishes can disguise a segment of mischief, but not joints that step or crowning alongside column strips. Think roughly wheel paths. On one West Campus scholar housing process, rolling carts made the associated complaint each and each and every circulate-in weekend. The deviation map confirmed a light ridge for the period of the hall during which two pours kissed badly. A sixteen-inch giant grind path eliminated the ridge for a higher year’s parade of mini fridges.

Reality IMT Inc.

3300 N Interstate Hwy 35, Austin, TX 78705

Phone wide variety: 512-814-5580

From experiment to BIM and returned again

Floor tips has value previous the existing turnover. If you should be would becould very well be asserting an as-equipped model for centers teams, upload the flooring surface as a reference. It supports with ways set-downs, fate remodels, or maybe leak detection mapping. Many three-d Laser Scanning Services will reward lightweight meshes that Revit can digest with out a grinding to a halt. If fashion efficiency matters, ask for tiling or region-of-ardour exports. No one wishes 40 million facets to observe a 2 hundred square foot restroom.

There can also be a case for scanning later in the task. If a spot has been abused by the use of exchange traffic, skids, and lifts, a temporarily rescan previously finishes cross down can store arguments. On a grocery construct-out in South Austin, shelving installers blamed floor, ground blamed slab, and the agenda blamed absolutely everyone. A equal-day experiment showed two forklift rut lines telegraphed into the flooring. Insurance included the repair in view that the documentation in fact separated the same old slab from the post-advent placed on.

Choosing a 3-D Laser Scanning Service Austin groups will also be counted on

A solid service brings higher than hardware. They carry conduct. Ask how they tie scans to control, what their registration residuals seem to be, and the way they guard reflectivity on epoxy or moist surfaces. Request sample stories with both fantastically portraits and uninteresting numbers. Look for 3-D Building Scanning Services with the intention to pivot among short-turn field assessments and deeper analytics whilst the mission turns messy. If they can deliver an cause of their mesh filtering judgements with out jargon, they in general comprehend what they are going to be doing.

One practical experiment is to give a company a small pilot discipline, five,000 sq. toes, and assessment their deviation map to a really good straightedge survey. They will no longer suit factor-for-factor, however the kinds must at all times align. If the scan presentations a lake in which your straightedge discovered a lake, amazing. If it reflects a wasteland in which you stumbled on a mountain, ask why. Sometimes modeling possibilities clarify it. Sometimes the web web site had movement among surveys. The level is to construct have confidence past you guess a surface conclude at the output.

Practical box notes from Austin jobsites

Morning scans beat afternoon scans in summer. Heat shimmer can have an impact on lengthy photography, and current pours a bay away can mirror like mirrors. If a slab stays to be damp, count on just a little bigger noise and plan for additonal filtering. Tape off reflective stainless thresholds or quilt them with kraft paper for the duration of scanning. Use small reference markers on monotonous floors so registration tool software has steady qualities. Keep persons transferring all through trap; a desk bound worker on their cellular will become a ghost statue throughout the factor cloud that you just would later delete.

Do not miss out on the dull stuff: batteries charged, tripods checked, firmware up-to-date. Keep silica dust protocols in mind in the event you scan for the time of grinding, in view that you will percent a room with vacuums and filters. If the web site is dusty and your scanner uses an inside fan, give it a minute to purge except now packing. It is machine, no longer a tank, and it appreciates care.

What the deviation map primarily appears like to give up users

Color maps can both inform or confuse. A limited shade ramp works better than a rainbow that screams over trivial differences. Use amazing steps, like zero to at least one/sixteen inch, 1/sixteen to at least one/eight inch, 1/eight to 1/four inch. Label the legend actually and encompass a straightforward north arrow, grids, and room tags. Add callouts in which the plan merits a transient sentence: “Low, 0.22 inch; plan to fill,” or “High along beam strip, think about grind.” A second sheet with the same map even though with contours at 1/eight inch periods enables veterans who suppose in traces in situation of blocks of color.

Why finished establishing scans routinely rely even whenever you most effective care approximately floors

Floors do now not exist in isolation. If the constitution deflects, the slab follows. 3d creation scanning of the shell grants context. On a cutting edge workplace difficulty off South Lamar, we scanned columns and beams along with the floor to identify a vigor slope closer to the east wall. The steel had a regularly occurring camber, set up effectually, that resolved below load. The slab grow to be top quality. The construction turned smiling scale back than its very very own weight. That suggestion remodeled the communique with the proprietor from blame to physics, and we left the ground by myself.

Similarly, scanning walls reflects the area baseboards will inform on you. If the floor rises on the window wall, the bottom will become a protracted wedge. A little tuck at the ground of the gypsum or a choice of taller base can conceal a fractional inch and store the obvious brand new. These are the small choices that a finished 3-d Building Scanning Services tools supports.

A quick, legitimate example: from pour to polish

Pour at five a.m., trowel by nine, medical care compound by means of through midday. The next morning, a 3-D Laser Scanning Austin team arrives at 6 previously than the electricians swarm. Twelve setups cowl 22,000 sq. feet. The subject time is below two hours with the aid of the group planned scan stations round obstructions. The comparable day, registration finishes with a network mistakes underneath 3 millimeters. A aircraft defined from format elevation turns into the reference. The deviation map reveals 7 % of the domain outdoor a 1/8 inch threshold, generally lows near the mechanical room and highs along gridline E. A prompt assembly at 4 p.m. assigns grind zones totaling 1,two hundred sq. toes and patch zones totaling 350 rectangular toes at 1/8 to three/16 inch. By the give up of the week, a rescan verifies the fix. Polishing starts Monday, and the owner never hears the terms “we’ll prefer to come back lower back.”

A compact record for businesses adopting scanning

- Decide your threshold up the front situated on end necessities, then shade maps to that threshold so choices are automatic. Tie scans to demonstrated handle, now not assumptions, and be sure residuals in advance you belif the map. Deliver two perspectives: a sleek color deviation map and a contour map, either annotated to grid and rooms. Close the loop with a targeted rescan after remediation, notwithstanding if it's going to be just the affected zones. Archive the surface floor to your style for long run paintings, and become aware of any intentional slopes so no man or women “fixes” them later.

The quiet payoff: fewer arguments, cleaner flooring, stronger sleep

No technological know-how makes bad concrete first-rate, but the appropriate measurements make problem small and early. That is the promise of 3-d Laser Scanning Services when used with judgment. On an Austin undertaking, with all its moving constituents and daring schedules, having a truthful map of your flooring is like conserving the preferable flashlight whilst the energy trips. You see the position to step. You steer clear of the puddle. You stop on time, and your punch list remains a punch listing, now not a singular.

Whether you're a frequent contractor development your QA toolbox, a ground subcontractor attempting to appear after your margins, or an owner who in effortless terms wishes flooring that do not wave at company, the trail is discreet. Bring in a three-D Laser Scanning Service Austin teams trust, test on the suited instances, and permit information layout the plan. The floor will still have a persona. It just will now not marvel you.